Pyrolytic Jet Propellant Engineering in 2025: Inside the Next 5 Years of Disruption, Innovation, and High-Stakes Competition Transforming Aerospace Fuel Technologies.

Pyrolytic Jet Propellant Breakthroughs: What’s Fueling Billions in Investments by 2025?

Table of Contents

- Executive Summary: Market Trends and Key Takeaways

- Pyrolytic Propellant Chemistry: Advances and Innovations

- Current State of the Pyrolytic Jet Propellant Market (2025)

- Leading Players: Manufacturers, Suppliers, and Industry Alliances

- Commercial and Military Applications: Market Segmentation and Demand Drivers

- Emerging Technologies: Catalysts, Reactors, and Process Optimization

- Sustainability and Regulatory Outlook: Environmental Impact and Compliance

- Investment Landscape: Funding, M&A, and Strategic Partnerships

- Market Forecasts: Growth Projections Through 2030

- Future Outlook: Challenges, Opportunities, and Game-Changing Developments

- Sources & References

Executive Summary: Market Trends and Key Takeaways

Pyrolytic jet propellant engineering is undergoing rapid transformation in 2025, driven by advancements in sustainable feedstocks, thermal decomposition techniques, and the increasing demand for high-efficiency aviation fuels. The sector is witnessing a convergence of aerospace, energy, and chemical engineering expertise to address environmental mandates and operational performance.

Key market trends include the integration of pyrolysis-based synthesis pathways to produce jet fuels from renewable sources such as biomass, municipal waste, and industrial byproducts. Major aerospace manufacturers are prioritizing drop-in synthetic aviation fuels to meet both regulatory and consumer demands for lower life-cycle emissions. For example, Boeing has publicly committed to supporting the transition to 100% sustainable aviation fuels (SAF) by 2030, with ongoing research into pyrolytic and thermochemical conversion processes as part of their sustainability strategy. Likewise, Airbus is actively collaborating with fuel producers and technology providers to accelerate the adoption of pyrolytic SAF, aiming for full fleet compatibility within this decade.

In 2025, several commercial-scale demonstration projects are operational or nearing completion. Shell, for instance, has announced pilot initiatives focused on pyrolysis-derived jet fuels, leveraging waste plastics and biomass as primary feedstocks. These initiatives are being scaled up to supply fuel for test flights and early commercial adoption. TotalEnergies is investing in integrated biorefinery concepts that include pyrolytic conversion modules, targeting both regional and intercontinental aviation markets.

The technical outlook is shaped by ongoing improvements in catalyst performance, reactor design, and product upgrading, which are critical for meeting stringent jet fuel specifications (e.g., ASTM D7566). Organizations such as International Civil Aviation Organization (ICAO) are updating certification protocols to accommodate a broader range of pyrolytic fuel pathways, enhancing market entry prospects for new producers. Supply chain integration, especially secure sourcing of consistent feedstocks, remains a central challenge.

Looking ahead, the pyrolytic jet propellant market is expected to expand as government incentives and carbon reduction targets incentivize both established and emerging players to accelerate commercialization. Strategic partnerships between airlines, fuel technology developers, and infrastructure providers are essential to scaling production and distribution. The next few years will likely see increased investment in pilot plants, expanded regulatory acceptance, and early adoption by forward-looking carriers aiming to differentiate through sustainability leadership.

Pyrolytic Propellant Chemistry: Advances and Innovations

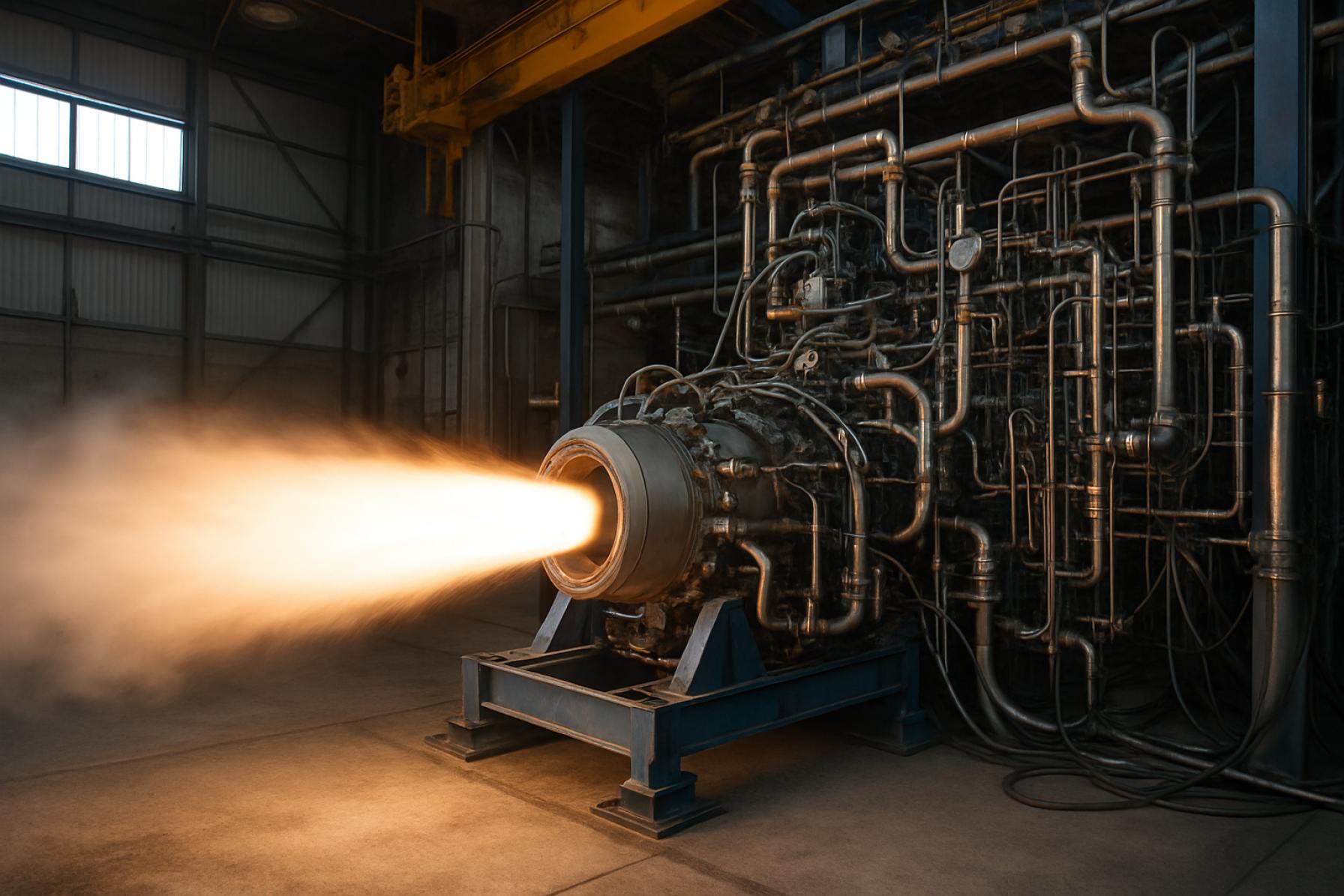

Pyrolytic jet propellant engineering is experiencing significant advances as the aerospace sector seeks alternative fuel solutions that balance performance, sustainability, and cost. Pyrolytic processes, which thermally decompose biomass or waste feedstocks in the absence of oxygen, have emerged as a promising pathway for developing renewable jet fuels with desirable energy densities and combustion characteristics.

In 2025, several major aerospace and energy companies are scaling up their research and pilot projects to validate pyrolytic jet fuels for aviation. Notably, Shell and TotalEnergies are both investing in advanced pyrolysis technologies to convert non-edible biomass and residual wastes into bio-oils, which can be further upgraded to synthetic paraffinic kerosene (SPK) suitable for use in jet engines. Demonstrations of pyrolytic SPK blends in turbine engines have shown promising results, with energy densities nearing that of conventional Jet A-1 and good compatibility with existing fuel infrastructure.

Recent chemical innovations center on optimizing the pyrolysis process for selectivity and yield. Catalytic pyrolysis—using zeolites or metal oxides—has been shown to increase the fraction of desired hydrocarbons while minimizing byproducts like char and gases. Companies such as GE Aerospace and Airbus (through collaborative research programs) are evaluating how these tailored pyrolytic fuels perform in engine tests, focusing on combustion stability, emissions profiles, and thermal management.

Regulatory agencies are also accelerating pathways for certification. The ASTM International committee on aviation fuels has prioritized fast-tracking technical evaluation for next-generation bio- and synthetic fuels, including those derived from pyrolysis, aiming for additional approvals under ASTM D7566 by 2026. This is expected to further incentivize commercial deployment.

Looking ahead, the outlook for pyrolytic jet propellant engineering is robust. The International Air Transport Association (IATA) projects that sustainable aviation fuel (SAF) production, including pyrolytic pathways, could supply up to 10% of global jet fuel demand by 2030. Ongoing advances in feedstock logistics, reactor scale-up, and fuel upgrading chemistries are likely to reduce costs and emissions, positioning pyrolytic propellants as a key enabler for decarbonizing aviation in the coming years.

Current State of the Pyrolytic Jet Propellant Market (2025)

As of 2025, pyrolytic jet propellant engineering stands at the intersection of innovation and market-driven demand for sustainable, high-performance aviation fuels. The field centers on the conversion of hydrocarbon-rich feedstocks—such as biomass, waste plastics, and other organic materials—into advanced jet fuels through pyrolysis, a thermochemical decomposition process conducted at elevated temperatures in the absence of oxygen. This approach is gaining significant traction due to its potential to reduce lifecycle greenhouse gas emissions and diversify the fuel supply chain for both commercial and defense aviation sectors.

The current market landscape is shaped by prominent aerospace and energy sector collaborations, government-backed initiatives, and scaling investments in production capacity. For example, Shell and Boeing have both announced partnerships and pilot projects focusing on the commercialization of pyrolytic synthetic aviation fuels, targeting ASTM D7566 certification for blending with conventional jet-A fuels. Similarly, TotalEnergies is actively developing proprietary pyrolysis processes to convert agricultural and forestry residues into jet-range hydrocarbons, aiming to reach commercial-scale output by 2027.

On the technology front, engineering advancements over the past year have centered on reactor design, feedstock flexibility, and upgrading crude pyrolysis oil into jet-fuel-range alkanes and aromatics. Companies like Velocys are piloting modular reactor systems capable of handling mixed waste streams, while LanzaTech integrates microbial upgrading of pyrolysis vapors to further refine product quality. These innovations seek to address challenges in process efficiency, fuel purity, and cost-competitiveness with fossil-derived jet kerosene.

Industry data from 2025 indicate that global production of pyrolytic jet fuels is still in the early stages, with output estimated at less than 0.1% of total aviation fuel consumption. However, announced projects and facility expansions signal rapid scaling capacity: Neste and Airbus have committed to advancing sustainable aviation fuel (SAF) supply chains, including pyrolysis-derived options, for both commercial airlines and military customers.

Looking ahead, the outlook for pyrolytic jet propellant engineering is closely tied to regulatory frameworks and market incentives. The International Air Transport Association (IATA) and national agencies such as the U.S. Federal Aviation Administration (FAA) continue to set ambitious emissions reduction targets, creating a favorable climate for research, pilot deployments, and commercial offtake agreements. The next few years are expected to see increased demonstration flights, standardization initiatives, and the integration of pyrolytic SAF into airport fueling infrastructure, paving the way for broader adoption by the end of the decade.

Leading Players: Manufacturers, Suppliers, and Industry Alliances

The landscape of pyrolytic jet propellant engineering in 2025 is marked by the active participation of established aerospace companies, innovative startups, and strategic industry alliances. As the demand for high-energy density, cleaner-burning jet propellants grows—driven by both military and commercial aviation needs—several key players have emerged at the forefront of manufacturing, supply, and systems integration.

- Northrop Grumman continues to lead in the development and supply of advanced propulsion systems, including pyrolytic-based fuels for specialized military and space applications. The company’s ongoing investments in propellant chemistry and manufacturing scalability facilitate integration with next-generation jet and rocket engines. Northrop Grumman’s collaborations with the U.S. Department of Defense and allied partners underscore its pivotal role in propellant supply chains (Northrop Grumman).

- Aerojet Rocketdyne, now a subsidiary of L3Harris, maintains significant focus on novel propellant formulations, including pyrolytic and hybrid systems. The company’s facilities in California and Alabama have expanded capacity for pilot production of advanced fuels, supporting both government programs and commercial initiatives (Aerojet Rocketdyne).

- Evonik Industries, a global leader in specialty chemicals, supplies critical feedstocks and additives necessary for the controlled pyrolysis processes used in high-performance jet fuels. Their partnerships with aviation OEMs and propulsion system designers enable tailored material solutions for pyrolytic engineering (Evonik Industries).

- Honeywell Aerospace is advancing pyrolytic propulsion through its integrated systems engineering and component manufacturing. Their involvement extends from fuel sensors and management systems to auxiliary power units designed to optimize new-generation propellants, reflecting a holistic approach to jet propulsion innovation (Honeywell Aerospace).

- Industry Alliances: In 2025, consortia such as the Aerospace Industries Association (AIA) and the NASA Technology Transfer Program have intensified collaboration on pyrolytic fuel standards, safety protocols, and certification pathways. These alliances foster pre-competitive research and facilitate technology transfer between defense, commercial aviation, and research institutions.

Looking ahead, continued investment and collaboration among these manufacturers, suppliers, and alliances will be crucial for scaling up pyrolytic jet propellant production, optimizing fuel properties, and meeting evolving regulatory and environmental requirements through the late 2020s.

Commercial and Military Applications: Market Segmentation and Demand Drivers

Pyrolytic jet propellant engineering, which leverages thermal decomposition processes to generate high-energy fuels, is experiencing a surge in both commercial and military aviation sectors as of 2025. This growth is driven by the demand for higher efficiency, lower emissions, and enhanced performance in jet propulsion systems. Pyrolytic processes offer the potential to produce synthetic fuels with tailored molecular structures, optimizing combustion characteristics for advanced turbine engines.

In the commercial aviation market, airlines and aircraft manufacturers are increasingly exploring pyrolytic jet fuels as part of their decarbonization strategies. The International Air Transport Association (IATA) continues to stress the role of sustainable aviation fuels (SAF), including those derived from pyrolysis of biomass and waste, in achieving net-zero emissions by 2050. Companies like Shell and TotalEnergies are investing in pilot-scale and demonstration projects to evaluate the scalability of pyrolytic fuel production and integration into existing supply chains. In 2025, Shell announced expanded trials of pyrolytic synthetic paraffinic kerosene (SPK) blends on select commercial flights, signaling growing confidence in the technology’s readiness for broader deployment.

Military applications represent a parallel and significant segment for pyrolytic jet propellant engineering. Defense organizations prioritize fuels that offer improved energy density, storage stability, and operational flexibility in extreme conditions. The U.S. Department of Defense, through collaborations with Defense Logistics Agency Energy and research institutions, is evaluating pyrolytic fuels for tactical jet platforms and unmanned aerial vehicles (UAVs). The unique ability of pyrolytic processes to convert a wide range of feedstocks—including waste plastics and biomass—into high-performance jet fuels supports military objectives for energy security and supply chain resilience. Naval Research Laboratory has been actively testing pyrolytic fuels for compatibility with Navy fighter jet engines, focusing on drop-in characteristics and cold-weather performance.

- Commercial drivers: decarbonization mandates, operational cost reductions, and brand differentiation via sustainability.

- Military drivers: energy independence, logistical resilience, and performance in diverse operational theaters.

Looking ahead, the next few years are expected to see increased certification activity, expanded flight trials, and the establishment of commercial-scale pyrolytic jet fuel plants. Regulatory frameworks are evolving to accommodate novel fuels, with ICAO and ASTM International playing key roles in standardization. Market segmentation will likely intensify as feedstock availability, regional policy incentives, and advances in reactor design shape the uptake of pyrolytic jet propellants across civilian and defense aviation domains.

Emerging Technologies: Catalysts, Reactors, and Process Optimization

The field of pyrolytic jet propellant engineering is undergoing significant transformation in 2025, driven by advancements in catalyst development, reactor design, and process optimization tailored for sustainable aviation fuel (SAF) production. Pyrolysis—thermal decomposition of organic materials in the absence of oxygen—offers a promising pathway to convert biomass and waste into jet-range hydrocarbons, with research and commercial initiatives accelerating globally.

A cornerstone of recent progress lies in catalyst innovation. Companies and research consortia are engineering catalysts that maximize selectivity for C8–C16 hydrocarbons—the carbon range ideal for jet fuel—while minimizing undesirable byproducts. For example, Shell and TotalEnergies have announced ongoing work in zeolite-based and metal-supported catalysts, aiming for higher conversion rates and longer operational lifetimes in continuous pyrolysis reactors. These advancements are crucial for scaling up from pilot to commercial production, as catalyst stability directly impacts operational costs and fuel consistency.

Reactor engineering is another focal area. The latest generation of fluidized bed and circulating fluidized bed reactors is being deployed to ensure uniform heat distribution and rapid vapor removal, both critical for maximizing liquid fuel yields and minimizing char formation. Velocys is actively developing modular reactor systems designed for distributed SAF production, leveraging process intensification to reduce footprint and energy consumption. These reactors are now being integrated with advanced condensation and separation units to further refine product quality.

Process optimization, driven by digitalization and real-time monitoring, is enhancing efficiency and scalability. Companies like Honeywell are deploying process control technologies across pilot and demonstration plants to monitor temperature, pressure, and product composition, enabling dynamic adjustment for optimal yields. Artificial intelligence and machine learning models are being implemented to predict catalyst deactivation and to schedule maintenance, reducing downtime and operational uncertainty.

Looking ahead, the combination of these emerging technologies is expected to drive down the cost of pyrolytic jet fuels while improving lifecycle greenhouse gas performance. Industry roadmaps suggest that, with continued innovation and regulatory support, commercial-scale deployment of pyrolytic SAF could become mainstream within the next five years, supporting the aviation sector’s decarbonization targets. Collaboration between technology developers, fuel producers, and airlines will be critical for overcoming remaining scale-up challenges and regulatory hurdles.

Sustainability and Regulatory Outlook: Environmental Impact and Compliance

The sustainability and regulatory landscape for pyrolytic jet propellant engineering is evolving rapidly, driven by increasing global pressure to decarbonize aviation and adopt cleaner fuel technologies. As of 2025, pyrolytic jet fuels—produced via the thermal decomposition of biomass or waste feedstocks—are emerging as a viable route towards Sustainable Aviation Fuel (SAF) compliance. These fuels can offer significant reductions in lifecycle greenhouse gas (GHG) emissions compared to conventional fossil-based jet fuels, aligning with regulatory targets set by aviation authorities worldwide.

In the near term, the International Civil Aviation Organization (ICAO) continues to advance its Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), which incentivizes airlines to adopt SAFs that demonstrate at least a 10% reduction in lifecycle emissions compared to baseline fossil fuels. Pyrolytic jet propellants, when derived from non-food biomass or municipal solid waste, are being recognized in CORSIA’s eligibility framework due to their potential for high GHG savings and waste reduction (International Civil Aviation Organization).

Regulatory agencies such as the U.S. Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) are actively collaborating with industry to update certification protocols for novel SAFs, including those produced via pyrolysis. The FAA’s Continuous Lower Energy, Emissions, and Noise (CLEEN) program has supported testing and validation of pyrolytic jet fuels for ASTM D7566 certification, a key standard for alternative jet fuel approval (Federal Aviation Administration). In Europe, the ReFuelEU Aviation initiative is setting ambitious mandates for SAF blending, aiming for at least 6% SAF in jet fuel by 2030, with pyrolytic fuels counted toward these quotas (European Commission).

From an industrial perspective, companies like Velocys and LanzaTech Global Inc. are advancing commercial-scale pyrolysis projects, with several demonstration plants scheduled to become operational within the next few years. These projects are designed to meet stringent emissions and sustainability criteria, with lifecycle analyses demonstrating GHG reductions of 70% or more relative to fossil jet fuel. Notably, these companies are also engaging in transparent reporting and third-party verification, anticipating more rigorous disclosure requirements under evolving EU and US regulations.

In summary, the outlook for pyrolytic jet propellant engineering is closely tied to regulatory acceptance and environmental performance. As policies tighten and SAF mandates expand globally, the sector is well-positioned for growth—provided it maintains robust compliance with emerging standards and delivers verifiable sustainability benefits.

Investment Landscape: Funding, M&A, and Strategic Partnerships

The investment landscape for pyrolytic jet propellant engineering is experiencing notable momentum as the aviation and aerospace industries prioritize decarbonization and sustainable fuel alternatives. In 2025, significant capital inflows are being directed toward companies developing and scaling pyrolysis-based jet fuel technologies. This trend is driven by both regulatory pressure for cleaner aviation and growing corporate commitments to net-zero targets.

A key development in early 2025 was the announcement by Shell of expanded investment in advanced biofuel production, with a focus on pyrolysis-derived synthetic aviation fuels. Shell’s strategy includes both direct funding for research and venture capital allocations targeting startups capable of commercializing pyrolytic processes at industrial scale. The company has also entered into supply agreements with airlines aiming to increase sustainable aviation fuel (SAF) uptake.

Mergers and acquisitions (M&A) activity in the sector is robust. TotalEnergies completed the acquisition of a significant stake in a US-based pyrolysis technology firm in late 2024, a move intended to secure proprietary process know-how and accelerate SAF production capacity. This acquisition aligns with TotalEnergies’ broader SAF roadmap, which targets 1.5 million tons of annual SAF production by 2030.

Strategic partnerships have become central to advancing pyrolytic jet propellant engineering. Airbus expanded its collaborative initiatives in 2025, partnering with several fuel technology startups and feedstock suppliers to co-develop scalable pyrolysis systems. These alliances are structured to integrate technology demonstration, certification, and supply chain optimization, enabling a faster transition from pilot to commercial deployment.

Government-driven funding mechanisms remain a significant catalyst. In 2025, the U.S. Department of Energy’s Bioenergy Technologies Office (Bioenergy Technologies Office) increased grant allocations to projects specifically focused on pyrolytic conversion pathways for SAF, with several million dollars earmarked for demonstration plants and feedstock logistics innovation.

Looking ahead, the next few years are expected to see intensified competition for intellectual property, continued venture capital activity, and further vertical integration via M&A as major energy players and aerospace manufacturers position themselves in the SAF value chain. The convergence of regulatory support, corporate sustainability targets, and technological maturation is likely to sustain high investment levels in pyrolytic jet propellant engineering through at least 2027.

Market Forecasts: Growth Projections Through 2030

The market for pyrolytic jet propellant engineering is positioned for significant growth through 2030, driven by advancements in sustainable aviation fuel (SAF) technologies and the global push for decarbonized aviation. Pyrolytic processes, which convert carbon-rich feedstocks such as biomass and waste into liquid fuels, are attracting increasing investment and attention from both established aerospace companies and innovative startups.

By 2025, several notable commercial and demonstration-scale facilities are expected to come online or ramp up production capacity. For example, Shell and TotalEnergies have announced plans to integrate pyrolysis into their SAF portfolios, targeting commercial output by the mid-2020s. LanzaTech is scaling up its gas fermentation and pyrolysis hybrid systems, with multiple airline partnerships aiming for steady SAF supply within this decade.

In the U.S., the Department of Energy’s Bioenergy Technologies Office is funding several projects to demonstrate high-yield pyrolytic jet fuel production, with a goal to reach at least 3 billion gallons of SAF production annually by 2030 (U.S. Department of Energy).

Current forecasts suggest the pyrolytic jet propellant sector will see a compound annual growth rate (CAGR) exceeding 20% through 2030, as regulatory frameworks such as the EU’s ReFuelEU Aviation initiative and U.S. SAF Grand Challenge set increasingly stringent SAF blending mandates. Demand is further bolstered by major carriers such as United Airlines and Air France-KLM making long-term offtake agreements with SAF producers, specifically referencing pyrolytic pathways for their scalability and feedstock flexibility.

- By 2026, operational capacity for pyrolytic jet fuels in North America and Europe is expected to surpass 500 million gallons per year, according to targets set by Veltia Fuels and Neste.

- Asia-Pacific is emerging as a growth hotspot, with ENEOS and Airbus collaborating on pyrolytic SAF projects aimed at supporting regional decarbonization goals.

- By 2030, over 5% of global jet fuel demand could be met by pyrolytic and other advanced SAFs, as projected by industry coalitions such as UK Civil Aviation Authority.

Overall, the outlook for pyrolytic jet propellant engineering is robust, underpinned by policy support, cross-sector collaboration, and ongoing technological improvements that are expected to further reduce production costs and improve lifecycle emissions performance through 2030.

Future Outlook: Challenges, Opportunities, and Game-Changing Developments

As the aerospace industry intensifies its pursuit of sustainable and high-efficiency propulsion, pyrolytic jet propellant engineering is positioned at a critical inflection point. In 2025, the sector faces both formidable technical hurdles and unprecedented opportunities, with developments poised to reshape jet fuel production, aircraft performance, and environmental impact.

One of the chief challenges remains the optimization of pyrolysis processes for consistent, scalable, and cost-effective production of synthetic jet fuels. The yield, energy efficiency, and quality of pyrolysis products—typically derived from biomass, waste plastics, or municipal solid waste—are heavily dependent on feedstock selection, reactor design, and downstream refining. Companies such as Shell and TotalEnergies have announced pilot and demonstration projects in 2024-2025 focused on improving catalytic pyrolysis and integration with existing refinery infrastructure, aiming for drop-in compatibility with current aviation turbine engines.

A major opportunity for pyrolytic jet propellant engineering is alignment with global regulatory and sustainability targets. The International Air Transport Association (IATA) and the International Civil Aviation Organization (ICAO) have both set ambitious carbon-reduction milestones for 2030 and beyond. This has spurred collaboration among feedstock suppliers, pyrolysis technology providers, and airlines. For instance, LanzaTech is advancing its alcohol-to-jet (ATJ) and gas fermentation technologies, while Velocys is scaling up waste-to-jet fuel plants in the UK and US, with commercial commissioning targeted for 2026.

The coming years are likely to witness several game-changing developments. Advanced reactor designs—including fluidized bed and microwave-assisted pyrolysis—promise higher selectivity and lower energy consumption. Also, digitalization and AI-driven process control are being implemented by firms like Siemens Energy to optimize yield and reduce downtime. New partnerships, such as those between Airbus and sustainable fuel innovators, are accelerating certification and adoption pathways for pyrolytic jet fuels in commercial aviation.

Nevertheless, uncertainties remain regarding long-term feedstock availability, product standardization, and market acceptance. The sector will need to address lifecycle emissions accounting, certification under ASTM D7566, and integration with airport fueling infrastructure. In summary, while technical and regulatory barriers persist, 2025 marks a period of rapid progress and investment, setting the stage for pyrolytic jet propellants to become a cornerstone of sustainable aviation in the near future.

Sources & References

- Boeing

- Airbus

- Shell

- TotalEnergies

- International Civil Aviation Organization (ICAO)

- GE Aerospace

- Airbus

- ASTM International

- IATA

- Velocys

- LanzaTech

- Neste

- Northrop Grumman

- Aerojet Rocketdyne

- Evonik Industries

- Honeywell Aerospace

- Aerospace Industries Association

- NASA Technology Transfer Program

- Honeywell

- European Commission

- Air France-KLM

- UK Civil Aviation Authority

- Siemens Energy